Stirling

Most engines exhaust lots of heat. The exhaust from engines can be about 600 or 700 degrees Fahrenheit or more. There is a lot of useable energy in the exhaust. But normally this energy is wasted. What the Stirling Cycle does is save the energy that’s in the exhaust from one power stroke so it can be used in the next power stroke. Of course this makes lots of sense. But it is difficult to do from a practical standpoint.

Recall that engines require compression. And recall that hot gas is very difficult to compress. So, how can the exhaust heat be efficiently put back into the engine? The heat energy can only be added after the gas is compressed; otherwise it would take too much energy or work to do the compression.

So, a Stirling engine has extra components and additional steps in its power cycle. After a power stroke, heat remains in the gas. The Stirling engine uses a displacer piston. The displacer piston moves the hot gas through a heat retaining device that saves the heat. After giving up heat to the heat retaining device, the gas is cooler. Then the gas is compressed. After it’s compressed the gas goes back through the heat retention device to pick up the heat that was left over from the last power stroke. Finally, more heat, in this case sunlight, is added to the gas to cause it to expand and make the next power stroke.

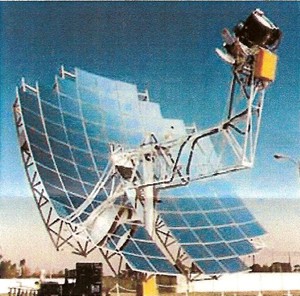

Prototype commercial concentrator with Stirling Generator

Another difference is that the Stirling engine is a closed loop. The gas in the cycle is not exhausted but rather re-circulated. The final heat is added via a high temperature heat exchanger such as the cavity receiver shown.

The complete power cycle requires heat to be heat is rejected via a low temperature heat exchanger.

In this case the Solar Stirling engine uses the sun as the power source for the high temperature heat exchanger. A closed loop Stirling engine, sometimes called a heat engine, is shown hereat the focus of the collector. This collector uses azimuth elevation tracking and high optical quality mirrors. This was the original technology proposed for the Sunrise Powerlink, a transmission system near San Diego. The point focus solar thermal power system was originally developed by JPL and tested at Edwards AFB.

What makes the Stirling engine more efficient is that it does not waste the exhaust heat, but rather uses it in the next power stroke. For more about the Stirling engine see the following article.